Imbedded and Continuously Supported Track System

In order to solve the problems of vibration and noise reduction, operation stability and maintenance of urban rail transit, Xinzhu, combined with Southwest Jiaotong University, Sichuan University and famous design institutes in China, developed the imbedded and continuously supported ballast-less track system.

At present, there are two types of imbedded tracks - the groove track and I-shaped track, widely used in the fields of tram, metro, light rail way, etc.

Advantages of Imbedded and Continuously Supported Track System

The new imbedded track allows the steel track to be imbedded in the concrete monolithic ballast bed.

It uses high polymer damping material for continuous support and continuously fastened steel track, which allows the track system to be advantaged in high quality, excellent stability, vibration and noise reduction, stray current and daily maintenance.

Application Area

At present, there are two types of structures: trough rails and I-shaped rails, which are widely used in trams, subways, light rails, and municipal areas.

Product

It can treat diseases such as rail wave grinding, vibration and noise exceeding standards, stray current corrosion, crossing molding and pavement damage. Provide services such as track disease test analysis, upgrade design and custom design and implementation

Application line: Existing line

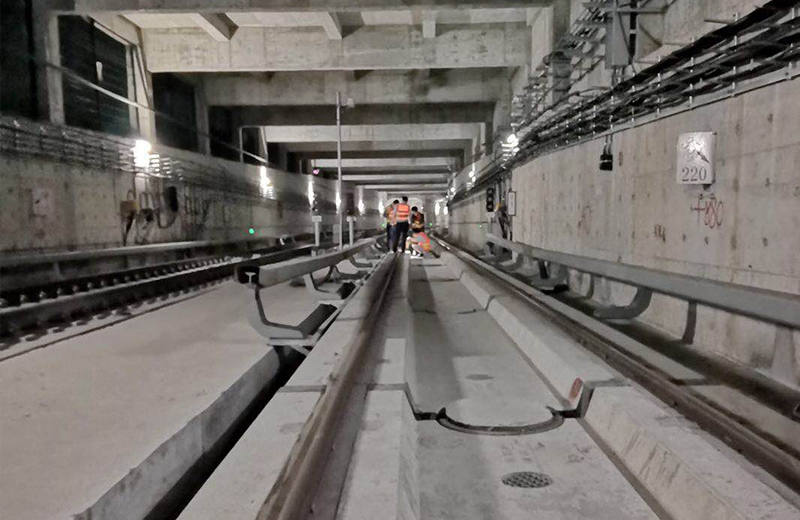

It is used for rail tracks in the depot of vehicles, which can effectively restrain the rails, the ground is flat, and the waterproof and insulation. At the same time, it has certain vibration and noise reduction effects.

Application Line: Inside Line of Vehicle Depot

Adapted axle load: ≤12.5t

Adaptable speed: ≤80km / h

Rail model: 59R2 / 60R2 grooved rail, 60 kg / m I-shaped rail, 50 kg / m I-shaped rail

Applicable ambient temperature: -40 ~ 50 ℃

Track structure height: ≥450mm

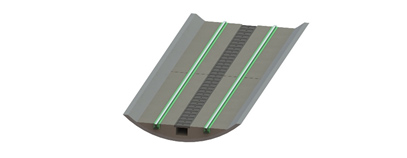

Application line: tram

Adapted axle load: ≤16t

Adaptable speed: ≤120km / h

Rail model: 59R2 / 60R2 grooved rail, 60 kg / m I-shaped rail, 50 kg / m I-shaped rail, 43 kg / m I-shaped rail

Applicable ambient temperature: -40 ~ 50 ℃

Track structure height: ≥200mm;

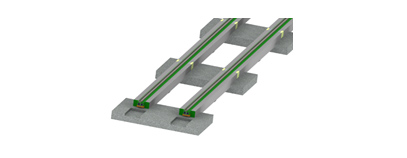

Application lines: trams, subways, municipal railways

Precast board to adapt to axle load: ≤17t

Adaptable speed: ≤160km / h

Rail model: 59R2 / 60R2 grooved rail, 60 kg / m I-shaped rail

Applicable ambient temperature: -40 ~ 50 ℃

Track structure height: subgrade section, bridge section ≥500mm; tunnel section ≥580mm;

Application lines: trams, subways, municipal railways

Embedded track

Engineering Case